28 February, 2023

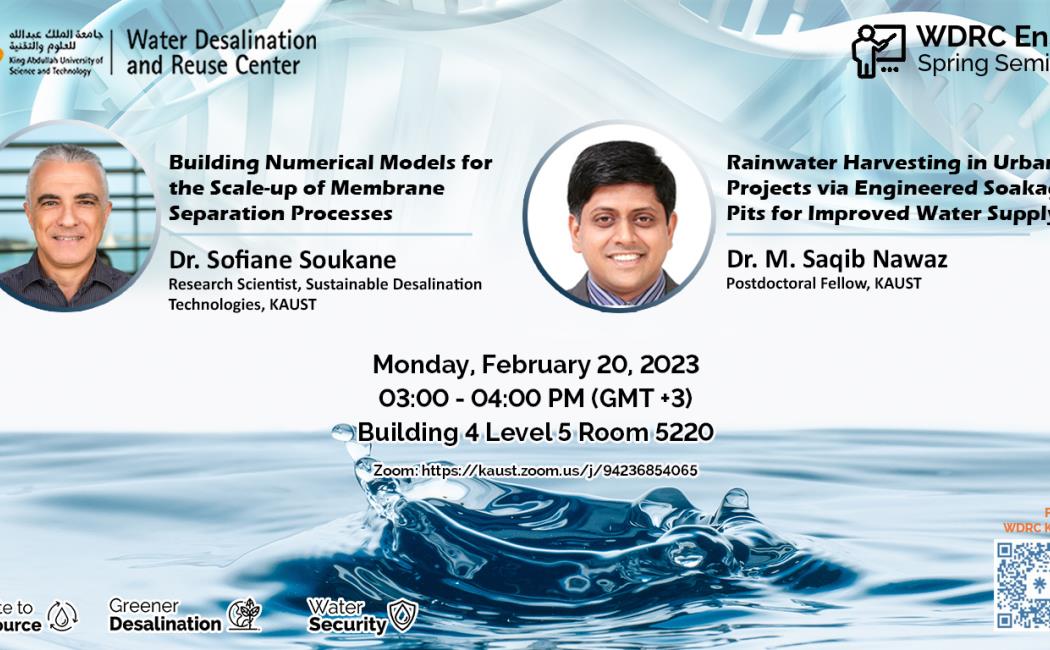

Building numerical models for the scale-up of membrane separation processes.

The scale-up of a chemical process consists of translating a laboratory prototype to a larger scale. This procedure is performed with the purpose of increasing the system productivity, which in the case of membrane separation processes such as membrane distillation or forward osmosis, is represented by the quantities of valuable fluids (water) or compounds (minerals) transferred through or retained by the membranes. Therefore, the scale-up procedure is associated with the size of the membrane active area offered by the system. Ideally, an increase in the membrane area would lead to the same increase in the ratio of productivity. Unfortunately, this linear relationship is seldom observed as strong non-linearity prevails in real life. Although separation occurs at the membrane interface, momentum, heat, and mass transfer, which strongly depend on equipment design, can limit the system's performance. At this stage, modeling and simulation are key to assessing how the system behaves at a larger scale without recourse to experimental trial and error. Recently developed models, which couple momentum, heat, and mass transfer to species transport across membranes, could help identify the required adjustments to sustain productivity by virtually increasing the equipment's size.

Please click the following link to watch: