Our primary focus lies in the development and enhancement of membrane-based desalination technologies, including Reverse Osmosis (RO), Membrane Distillation (MD), and Forward Osmosis (FO). This involves continuous improvement in RO and MD processes, as well as exploring hybrid processes to maximize freshwater production and energy recovery.

Forward Osmosis (FO): FO operates on natural osmotic pressure and does not require hydraulic pressure. This makes FO a suitable low-energy alternative for conventional desalination technologies. We have optimized FO operational parameters and design criteria to concentrate and reuse valuable industrial streams like textile dyebath effluent and produced water from oil exploration sites. The process optimization evaluates different operating temperatures, draw solutions types and concentrations, cross-flow velocities and pH levels. The membrane interaction with key foulants in the feed stream and its chemical stability in short-term and long-term batch and continuous experiments is also evaluated. We use different types of commercially available and in-house fabricated/modified flat sheet and hollow fiber FO membranes that serve the best purpose for our requirement.

Membrane Distillation (MD): MD utilizes vapor pressure of a stream as a driving force for mass transport across the membrane. The main advantage of MD is its ability to utilize low grade waste heat sources for vapor production. Secondly, the salinity limits of MD process is 3-4 times higher than RO, which makes it suitable for hyper-saline streams (brine, produced water) treatment. We have designed and optimized MD process to provide maximum water throughput and minimize fouling. We also evaluate different pre-treatment strategies to maximize the MD process stability and efficiency.

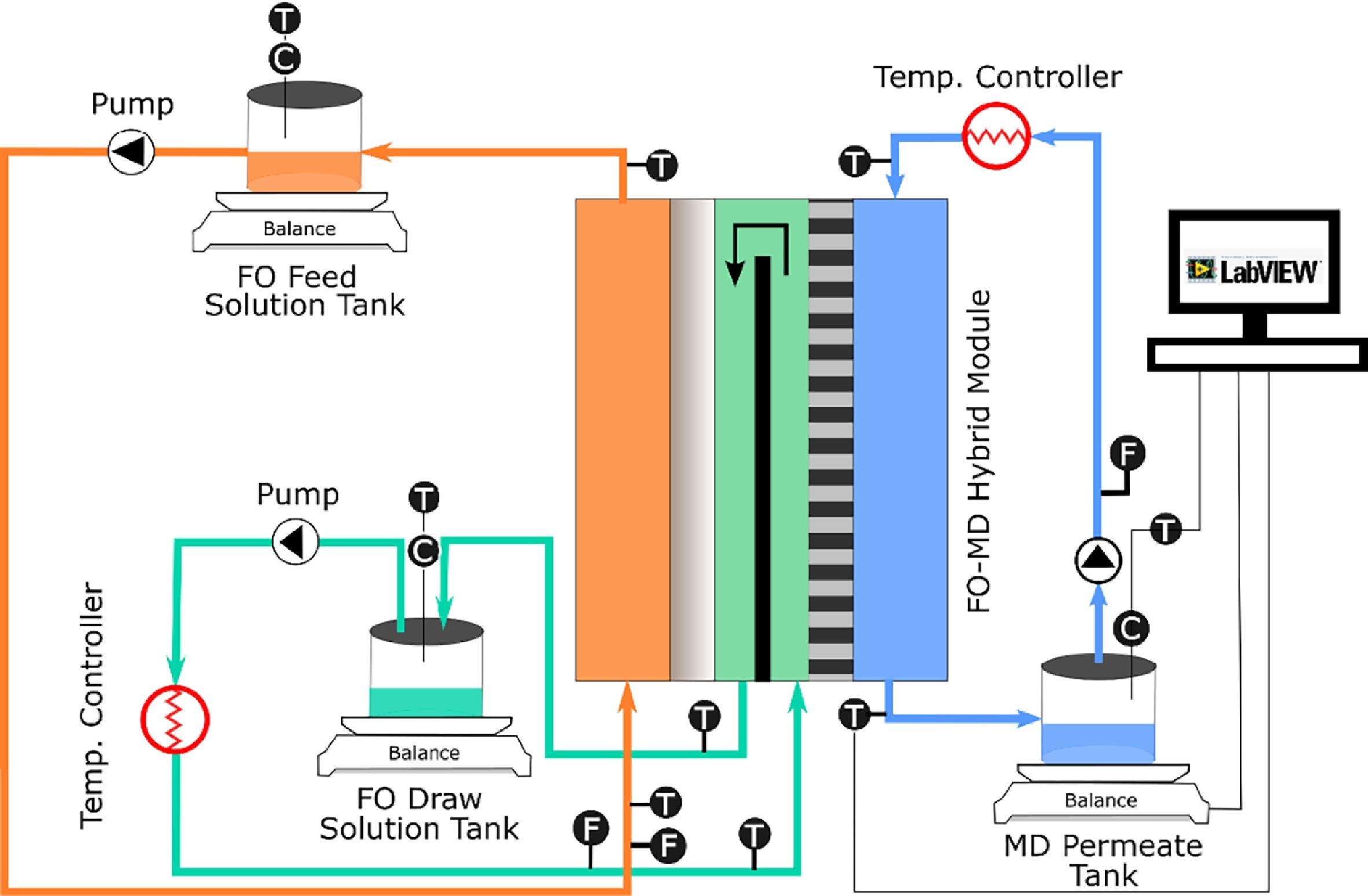

FO-MD Hybrid: We have designed and fabricated our patented integrated FO-MD hybrid module that houses both FO and MD membranes within the same module. This module comes with an osmotic and thermal isolation barrier to minimize the heat losses and maximize the thermal and osmotic potential of the feed and draw solution streams. We have successfully utilized this module for the simultaneous treatment of different real produced water streams originating from the same oil exploration sites.

We are also trying to hybridize other technologies that have the potential to complement each other and are more energy efficient in combination.